Lignin Industries materials for ABS applications.

Renol® helps manufacturers meet sustainability goals without compromising on material strength or quality.

Renol® masterbatches for ABS applications

Introducing Renol® for ABS:

Our Renol®masterbatches cut down reliance on fossil-based materials while maintaining functionality, with a significantly reduced carbon footprint.

Renol® is made from 100% biobased materials: lignin and biobased oils. When we supply Renol® as a masterbatch, we blend it with a carrier polymer (the plastic material our customer will blend our Renol® with). In our portfolio you can choose between two alternatives: either Renol® virgin ABS 5050 (50% Renol® and 50% virgin ABS) or Renol® recycled ABS 7030 (70% Renol® and 30 recycled ABS).

Our materbatches are versatile, suitable for extrusion and injection moulding, and integrates seamlessly into your existing operations—no adjustments in process equipment needed. It comes in granular form and works well with both recycled and virgin resins, offering a cost-effective alternative—blend up to 40% with ABS for maximum CO2 reduction.

Derived from a by-product of the forest industry, Renol® reduces fossil material usage and enables fully recyclable end products, contributing to a lower overall carbon footprint.

Benefits

Drop-in sustainability additive, no special accommodations needed

Compatible with standard additives and impact modifiers

Works with conventional moulding equipment and tooling

Renol® masterbatch does not affect the recyclability of end products when combined with recyclable materials

Its natural color is a brown, reminiscent of the trees from which it is derived

Possibility to colour in to other colours, except white and transparent colours

Strong forest and circular narrative

Market fit

Automotive & mobility

Consumer electronics

Housing appliances

Storage systems

Furniture

Growing trees act as a carbon sink, absorbing more CO2 than they release, making Renol® a carbon-negative material and contributing to significantly lower CO2 footprints in the end products.

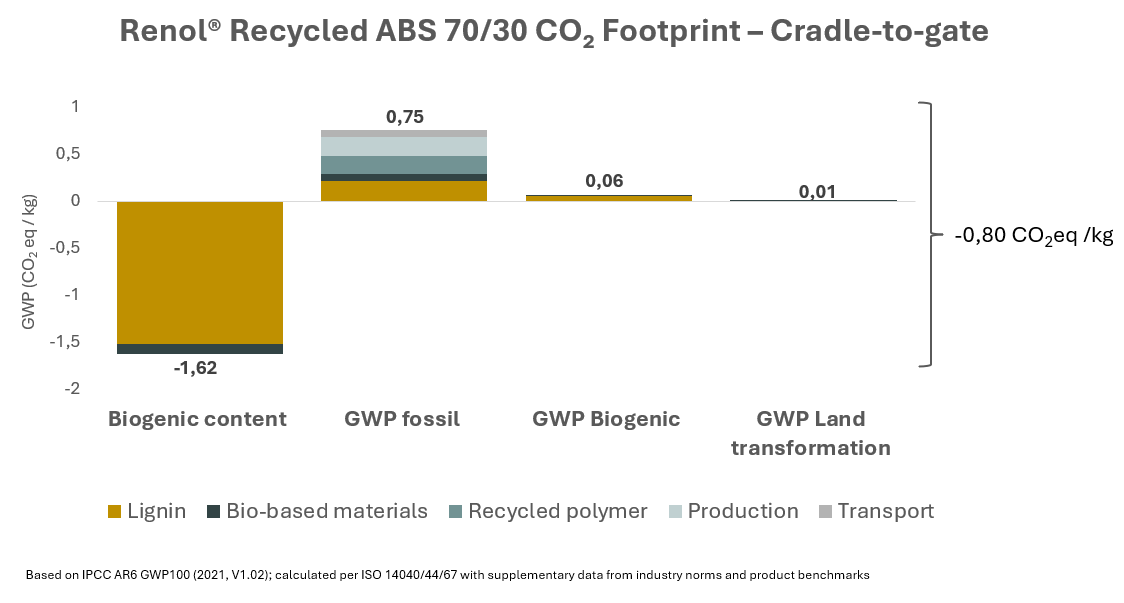

The Renol® masterbatch with recycled ABS—containing 70% Renol® and 30% rABS—has a total GWP of 0.82 kg CO2-eq./kg and a temporary biogenic carbon uptake of -1.62 kg CO2-eq./kg. In summary, this Renol® masterbatch has a CO2 footprint of -0.80 kg CO2-eq./kg. The cradle-to-gate carbon balance is net-negative, demonstrating that it offsets its own emissions and sequesters additional CO2 from the atmosphere—positioning it as the preferred option for climate-conscious applications.

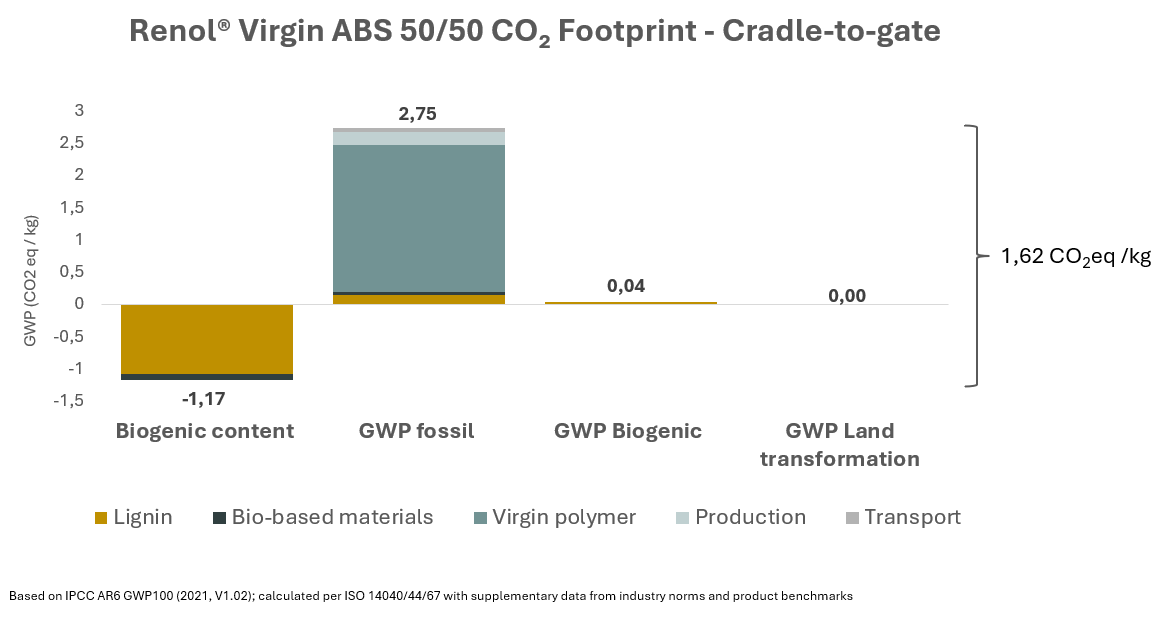

In comparison, the Renol® masterbatch with virgin ABS—containing 50% Renol® and 50% ABS—has a total GWP of 2.79 kg CO₂-eq./kg and a temporary biogenic carbon uptake of -1.17 kg CO2-eq./kg. In summary, this Renol® masterbatch has a CO2 footprint of 1.62 kg CO2-eq./kg.

Material Portfolio

for ABS

Renol® masterbatches with ABS

Renol® virgin ABS 5050 (a masterbatch with 50% Renol® and 50% virgin ABS) is our first lignin-based ABS masterbatch resulting in a 20% CO2 reduction in injection molded products compared to virgin ABS.

Launched in June 2025, Renol® recycled ABS 7030 (a masterbatch with 70% Renol® and 30% recycled ABS) is our latest innovation for maximized CO2 reduction of ABS plastics. Here the lignin-based formulation blended with recycled ABS enables up to 40% CO2 reduction compared to recycled ABS.

FAQs

-

Renol® is made from 100% biobased materials: lignin and biobased oils. When we supply Renol® as a masterbatch, we blend it with a carrier polymer (the plastic material our customer will blend our Renol® with, in this case ABS).

We offer two masterbatches with either virgin or recycled ABS blended with Renol®.

For the Renol® virgin ABS, the masterbatch is a blend of 50% Renol® and 50% virgin ABS. In the Renol® recycled ABS, 70% Renol® is blended with 30% recycled ABS.

-

No, Renol® pellets are primarily biobased, but they are not biodegradable according to EN standards. However, this is actually a benefit, as they are designed to be recyclable, contributing to a circular economy rather than breaking down into the environment.

-

Our material is ideal for applications that don’t require high-gloss finishes. It offers a refined colour range, from soft greys, pastels and to deep browns and blacks.

-

We focus on cradle-to-gate because it reflects the stages of production we directly control and take responsibility for, up until the material leaves our facility. What happens beyond that—how the material is used and disposed of—depends on the end user, which is outside our direct control.

However, cradle-to-grave data can be provided through collaboration with the end user for a more complete view of the product’s life cycle.Item description

How to purchase?

Please get in touch with our sales team to find out more or ask for a quote.