Lignin Industries materials for Thermoplastic elastomer applications

Reduce your carbon footprint with Renol®, a drop-in solution based on forest residues.

Renol® masterbatches for Thermoplastic elastomers – giving substantial CO2 reduction at a competitive price

New Renol® TPV – a groundbreaking material innovation

Our newly launched Renol® TPV is made of 70% Renol® and 30% elastomer additives. This 70% biobased composition enables optimal processability and end-product quality.

This important deep tech material innovation is designed for blending in polyolefin-based elastomers such as TPV. When mixed 60/40 with virgin TPV it provides up to 50% CO2 reduction in the end application (including conversion). And it comes at a competitive price.

Our Renol® TPV comes in granular form and works well with both recycled and virgin resins. They integrate seamlessly into your existing operations which means that no adjustments in process equipment are needed.

Benefits

- Drop-in sustainability additive, no changes needed in existing industrial set-up

- Enables up to 50% CO2 reduction in the end-product, by blending Renol® TPV with thermoplastic elastomers

- Improved oil-resistance and reduced swell compared to conventional TPV, ensuring stable performance and product quality

- Does not hinder recycling of end applications and thanks to its antioxidant features it can be re-processed several times without losing the mechanical properties

- Strong forest and circular narrative - its natural colour is brown, reminiscent of the trees from which it is derived

- Combining CO2 reduction with a competitive price level compared to conventional TPV materials

Product fit

2K overmoulding

Moderate-temperature seals

Bellows and protective covers

Caps and closures

Handles and grips

Impact-absorbing surface infill

What is Renol®?

Derived from lignin, a by-product of the forestry or agricultural industries, Renol® reduces fossil material usages and enables fully recyclable end products while maintaining functionality.

Reduce your carbon footprint with Renol® TPV

Growing trees act as a carbon sink, absorbing more CO2 than they release, making Renol® a carbon-negative material and contributing to significantly lower CO2 footprints in the end products.

Renol® TPV

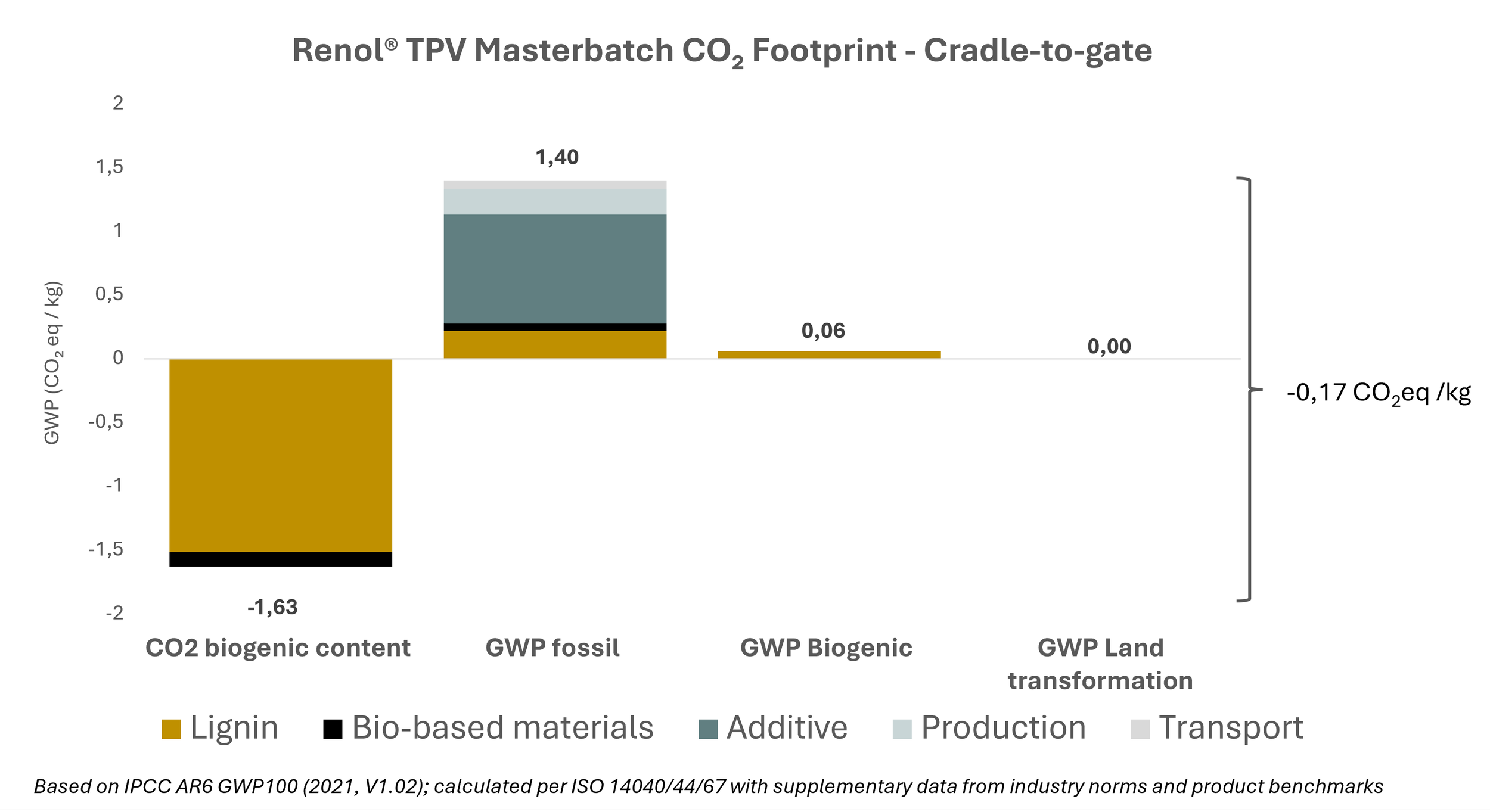

Our new Renol® TPV contains 70% Renol® and 30% elastomer. It has a total GWP of 1.46 kg CO2-eq./kg and a temporary biogenic carbon uptake of -1.63 kg CO2-eq./kg, leading to a CO2 footprint of -0.17 kg CO2-eq./kg. When mixed 60/40 with virgin TPV, a 50% CO2 reduction can be achieved in the end product (incl. conversion).

Material portfolio for Thermoplastic elastomers – documents for downloading

Renol® TPV masterbatch

FAQs

-

Renol® is made from 100% biobased materials: lignin and biobased oils. When we supply Renol® as a masterbatch, we blend it with a carrier polymer which is the plastic material our customer will use it with. In most cases the masterbatch is a 70/30 mix of Renol® and the carrier polymer. This means the masterbatch will have 70 % bio content.

-

Renol® does not hinder recycling of end applications neither in standard open- nor in closed-loop recycling streams.

-

No, Renol® pellets are primarily biobased, but they are not biodegradable according to EN standards. However, this is actually a benefit, as they are designed to be recyclable, contributing to a circular economy rather than being degraded.

-

Renol® has a natural brown color, coming from the trees from which it is derived. It’s possible to use Renol® for other colours, except white and transparent colours.

-

We focus on cradle-to-gate due to the fact that it includes activities we can control and thus assess; our raw materials, manufacturing and transports.

However, cradle-to-grave data can be achieved through collaboration with the end user to assess the usage and end-of-life phases.

How to purchase?

Please get in touch with our sales team to find out more or ask for a quote.